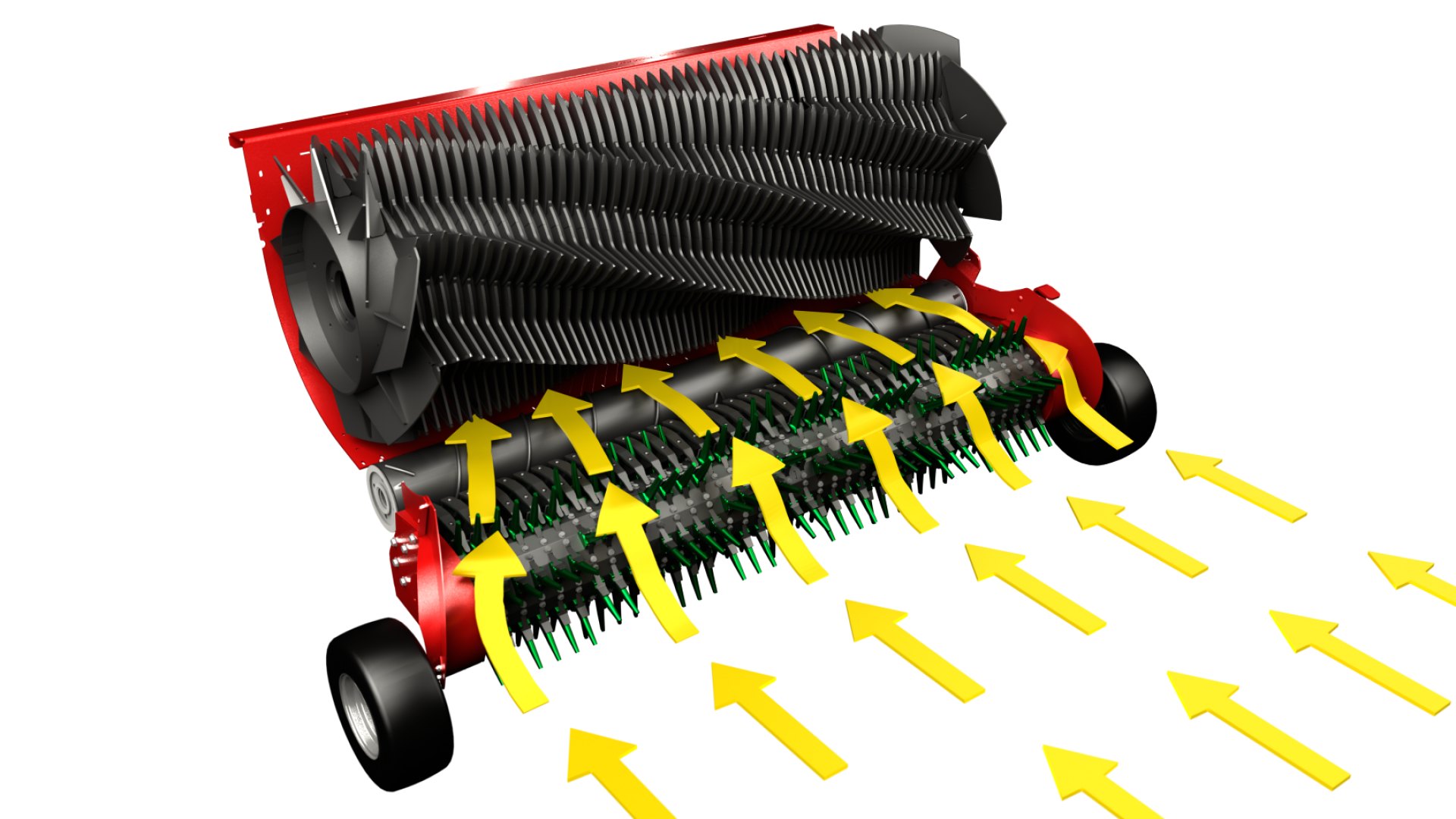

Continuous Flow System

The Continuous Flow System

Due to the interaction of different components, the Continuous Flow System ensures excellent easy towing with little power required.

Experience the unique continuous flow system. Continuous and quick flow of material with your Strautmann forage wagon.

The system ensures faster, more gentle and diesel-saving charging.

Cutting unit & rotor:

- Exact cutting due to perfect interaction

- Strippers and tines are arranged at a large angle to each other

- Welded-on tine plates ensure permanent precise cut

Pick–up: Gentle picking-up of grass and dispersal of swathe

- wide Pick-up

- Innovative plastic tines, for an unprecedented resistance to wear

- Flat standing pick-up for optimum adaptation to Ground

- 6 helically arranged segmented tine rows

- Optimum adaptation to ground

Continuous Flow-Roller: Dispersal and acceleration of material

- The Continuous Flow-Roller disperses the grass by means of the special welded-on layer

- Thus, grass is homogeneously conveyed to the rotor over the entire width

- Acceleration of material ensures homogeneous flow of material

- Always identical delivery of loaded material from pick-up to rotor

- No fodder piling up

Optimum filling degree over the entire width

- Reduced power requirement due to higher positioned rotor and thus shortened conveyor duct

- The material is conveyed into the cargo space over its total width

- Maximum and homogeneous filling degree = higher tonnage per m³

- Fast loading with less power required