New ISOBUS control for Strautmann universal spreaders

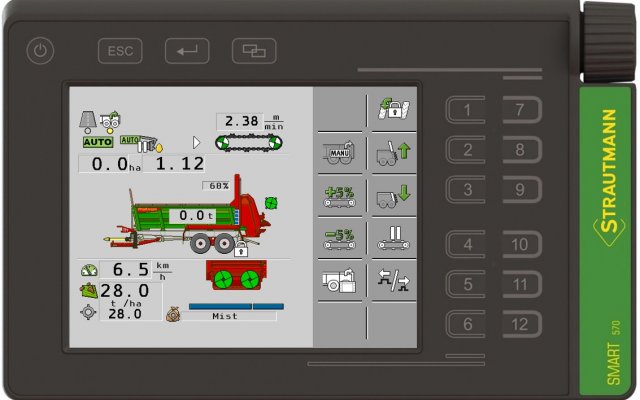

Strautmann is presenting a newly developed ISOBUS control for the universal spreader models of the VS and PS series at Agritechnica. Apart from an intuitive design with a lot of automatic functions and an improved control terminal, the new control impresses in particular by the option of dynamic weighing during discharge.

On the occasion of this year's Agritechnica, Strautmann is presenting a new generation of ISOBUS controls for universal spreader models. This easily and logically structured control ensures maximum precision during discharge of various spreading materials.

The control software distinguishes between three different operating modes "Charging – Road travel – Discharging". Depending on the operating mode, the operator has the frequently required functions directly at disposal. Thus, operation is easy and clear. Many additional automatic functions are integrated to make working even more comfortable. They can be individually switched on or off by the operator.

The desired discharge quantity can be achieved either manually, in volume-dependent or weight-dependent manner. In manual mode, the transport floor speed is set by the operator and thus fixed. When working in volume-dependent mode, only the desired discharge quantity in m³/ha must be specified. The control system then fully automatically sets the speed of the transport floor in relation to the speed of the tractor. Thus, the discharged quantity always remains the same. For machines equipped with scales, the weight-dependent control is additionally available. Here, the desired nominal value in t/ha is specified and the feed rate is set fully automatically as well.

The dynamic weighing function is a new feature. The control system permanently registers the weight reduction during discharge and compares it with the set quantity to be discharged. Thus, a discharge to the kilogramme is achieved under any conditions. This is a great advantage in particular in case of inhomogeneous spreading materials such as e.g. manure of different density.

The dynamic weighing function is a new feature. The control system permanently registers the weight reduction during discharge and compares it with the set quantity to be discharged. Thus, a discharge to the kilogramme is achieved under any conditions. This is a great advantage in particular in case of inhomogeneous spreading materials such as e.g. manure of different density.

In addition, the "Touch 800" terminal for maximum operating convenience and utmost accuracy during discharge is available. It has an 8" touch screen and is delivered in combination with a multi-function joystick. All joystick keys are freely assignable, which enables the driver to control individually. The terminal is equipped with a task controller, such that the discharge quantity can be controlled according to position and sub-area specific criteria via an application map. In combination with the dynamic weighing function, the terminal is also able to document the actually discharged quantity according to sub-area specific criteria. That means that the spreader can be used for Precision Farming without any restrictions.