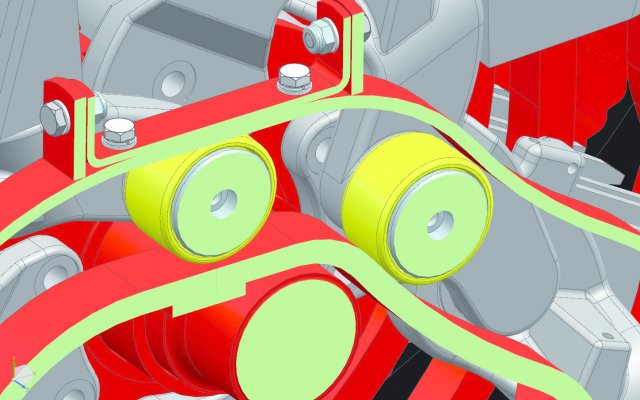

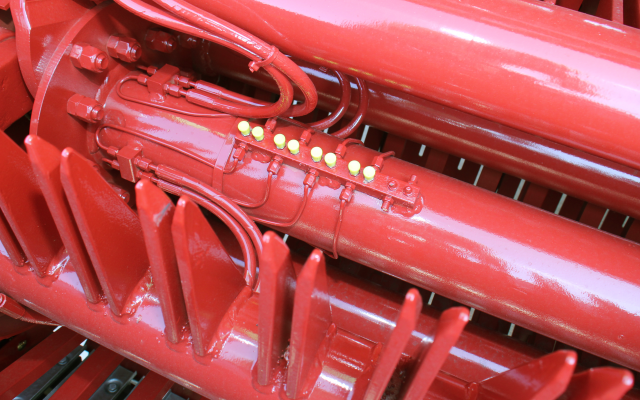

Tine-bar assembly

Tine bar bearing

- Lateral spherical bearings

- Twists of the tine bars are compensated for without any problems

- Low maintenance and wear

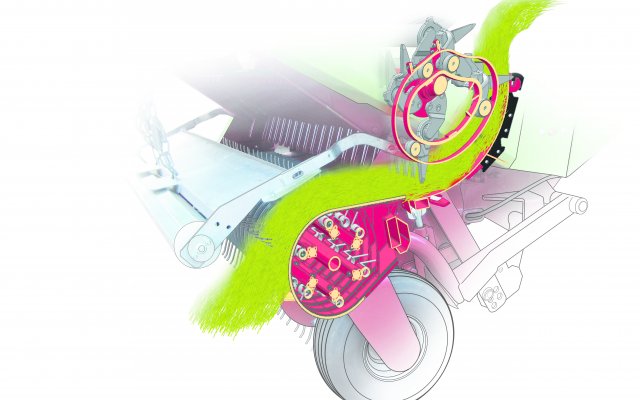

High harvesting performance

The two-sided curved path control enables

- Maximum harvesting performance

- Long service life

The double tines of the tine bars are guided at an optimum angle of 90° to the conveyor duct trough at any time.

- Low power required

- Exact cutting quality

- Extremely gentle fodder treatment

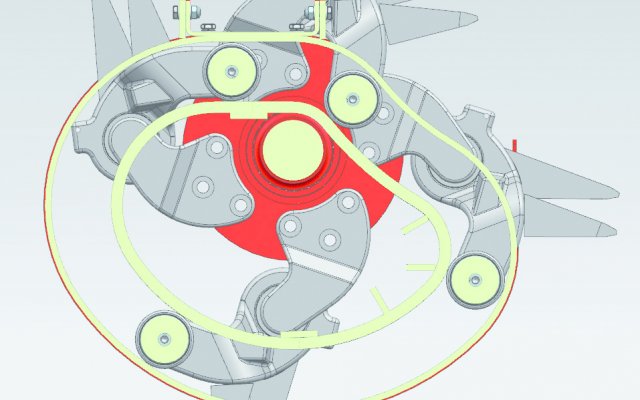

Four tine bars (standard Ambion 290 and 360)

- Particularly gentle

- Ideal for hay and light materials

Drive

- Tine bars powered via a solid Duplex chain

- Pick-up powered via a reinforced roller chain

Five tine bars (standard Ambion 440 and 500)

- High harvesting performance

- Durable

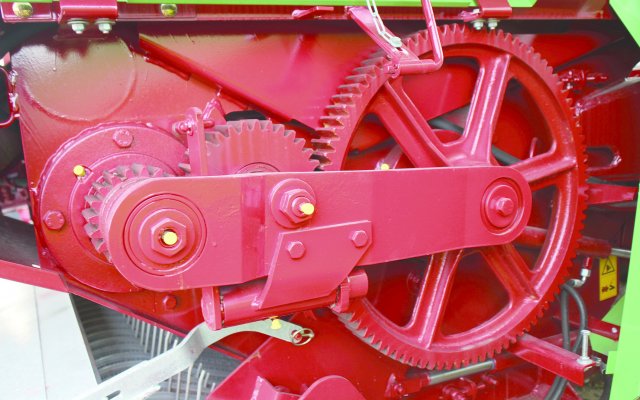

Drive

- Powered via solid toothed wheels

- The outer steel bridge prevents the shafts from deflecting when peak loads occur

- Toothed wheel wear due to one-sided abrasion is excluded

Quick-lubrication system

-

All lubricating nipples of the tine bars and

-

control bearings are centrally grouped

-

Lubricating with one rotor position without any problems

-

Time saving of up to 90% for this work